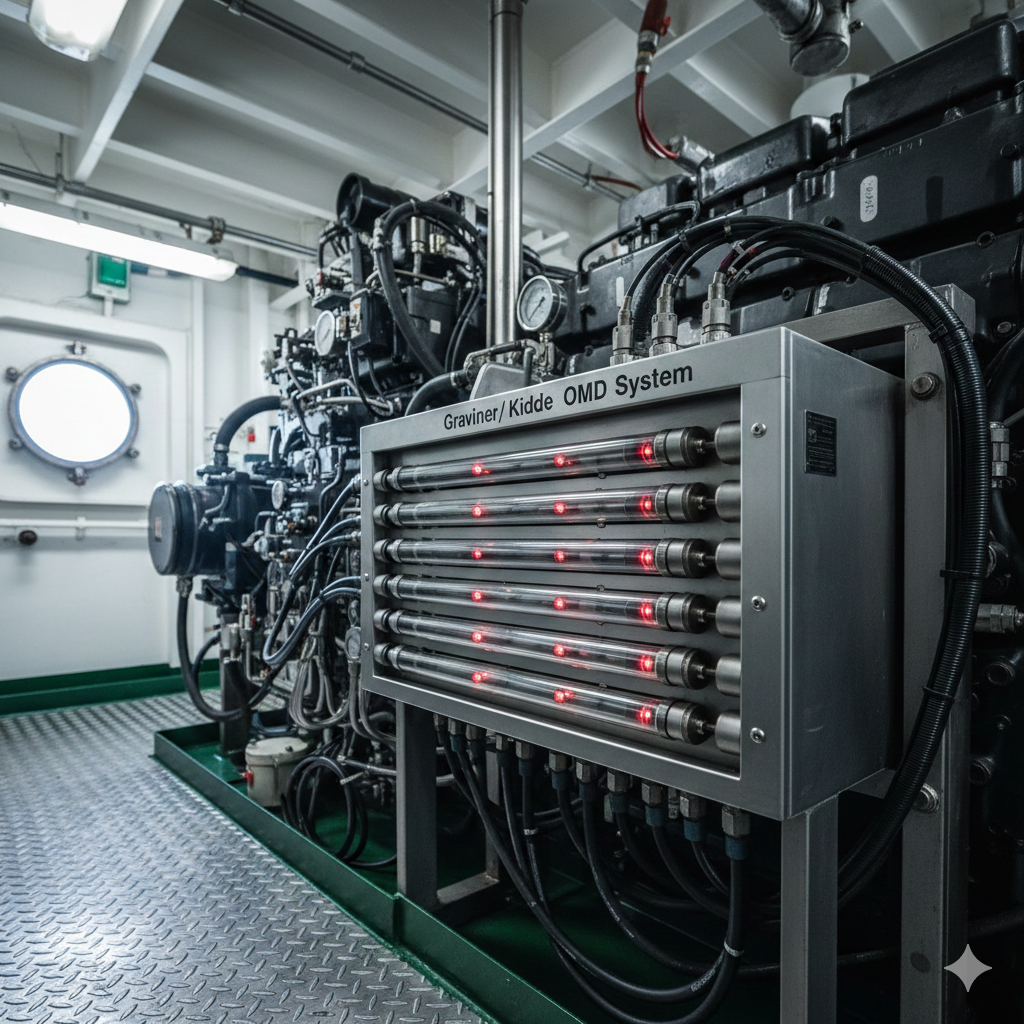

Graviner/Kidde OMD Systems: Reliable Oil Mist Detection for Ships and Offshore Vessels

Safety in marine and offshore operations depends heavily on early fault detection and effective monitoring systems. Among the most critical risks in large diesel engines is the formation of oil mist within the crankcase, which can lead to severe fires or explosions if not detected in time. This is why Graviner/Kidde OMD systems are widely recognized as a reliable solution for oil mist detection on ships and offshore vessels. Supported and supplied by RMS Marine Service, these systems play a vital role in safeguarding engines, crews, and assets across the maritime industry.

The Importance of Oil Mist Detection at Sea

Marine engines operate continuously under high temperatures, heavy loads, and challenging environmental conditions. When lubrication systems malfunction or engine components overheat, oil can atomize into fine mist particles. This oil mist is extremely flammable and can ignite instantly upon contact with hot engine surfaces.

Conventional monitoring methods may not detect this danger early enough. RMS Marine Service therefore emphasizes the importance of installing Graviner/Kidde OMD systems, which are specifically designed to identify oil mist at an early stage and prevent hazardous situations from escalating.

What Are Graviner/Kidde OMD Systems?

Graviner/Kidde OMD systems are advanced Oil Mist Detection solutions developed by globally trusted safety technology brands. These systems continuously monitor oil mist concentration inside marine engine crankcases using high-precision optical sensors.

When oil mist levels exceed safe limits, the system immediately triggers visual and audible alarms, allowing crew members to take prompt corrective action. With professional installation and support from RMS Marine Service, these systems deliver consistent and reliable performance on both ships and offshore vessels.

How Graviner/Kidde OMD Systems Ensure Reliability

Early Detection for Fire Prevention

One of the key advantages of Graviner/Kidde OMD systems is their ability to detect oil mist long before visible smoke, fire, or mechanical failure occurs. Early detection provides valuable time for engineers to reduce engine load or shut down machinery, preventing fires and explosions.

By working with RMS Marine Service, shipowners ensure optimal system configuration, accurate sensor placement, and reliable alarm response.

Continuous Monitoring for Marine and Offshore Operations

Ships and offshore vessels often operate for extended periods without interruption. Graviner/Kidde OMD systems offer 24/7 monitoring, ensuring that any abnormal increase in oil mist concentration is detected immediately.

RMS Marine Service supports this continuous operation by providing maintenance services, technical expertise, and guidance to keep systems functioning effectively throughout their service life.

Designed for Harsh Environments

Marine and offshore environments expose equipment to vibration, heat, humidity, and corrosive conditions. Graviner/Kidde OMD systems are built with robust marine-grade components to withstand these challenges.

With support from RMS Marine Service, these systems maintain long-term reliability even under demanding operating conditions.

Key Features of Graviner/Kidde OMD Systems

Graviner/Kidde OMD systems include several features that make them a trusted choice for ships and offshore vessels:

-

High-sensitivity optical sensors for accurate oil mist detection

-

Fast and reliable alarm activation to prevent escalation of engine faults

-

Scalable system design suitable for multiple engines and vessel sizes

-

Durable construction for harsh marine and offshore environments

-

User-friendly interfaces for easy monitoring and diagnostics

When supplied and maintained by RMS Marine Service, these features ensure dependable safety performance.

Compliance with Maritime and Offshore Safety Regulations

International maritime regulations and classification society rules require oil mist detection systems on large marine diesel engines. Installing certified Graviner/Kidde OMD systems helps vessels meet SOLAS and class requirements.

RMS Marine Service assists shipowners and offshore operators in achieving compliance by supplying approved systems and offering expert technical support and documentation.

Applications Across Ships and Offshore Vessels

Graviner/Kidde OMD systems are widely used across a range of maritime and offshore applications, including:

-

Cargo ships and container vessels for continuous engine protection

-

Tankers and bulk carriers where fire prevention is critical

-

Offshore support vessels operating in high-risk environments

-

Drilling rigs and offshore platforms requiring advanced safety monitoring

-

Passenger vessels and ferries to enhance crew and passenger safety

Through RMS Marine Service, these systems can be customized to meet the specific operational requirements of each vessel or offshore unit.

Why Choose RMS Marine Service for Graviner/Kidde OMD Systems

Choosing the right service provider is essential for reliable oil mist detection. RMS Marine Service offers comprehensive solutions, including system supply, installation guidance, maintenance support, and after-sales service.

By partnering with RMS Marine Service, shipowners and offshore operators benefit from industry expertise, genuine components, and dependable technical assistance, ensuring long-term safety and system performance.

Conclusion

Reliable oil mist detection is essential for preventing engine fires and protecting assets in marine and offshore operations. Graviner/Kidde OMD systems provide proven, early detection technology that enhances safety and operational reliability. With professional support from RMS Marine Service, these systems meet international safety standards while delivering consistent performance in demanding environments.

For ships and offshore vessels seeking dependable engine protection, Graviner/Kidde OMD systems supplied and supported by RMS Marine Service represent a smart investment in safety, compliance, and long-term operational efficiency.