Plastic Injection Mold Maker Influence on Product Development

A Plastic Injection Mold Maker plays an important role in modern manufacturing by designing and producing moulds used to form plastic components across many industries. These moulds determine the accuracy, strength, and appearance of the final products. Their work supports production lines that rely on consistent quality and reliable performance, making mould making a crucial part of the industrial landscape.

The first step for a Plastic Injection Mold Maker involves studying the desired product. This includes reviewing CAD models, evaluating part geometry, and identifying areas that may require structural support. By understanding the design in detail, the maker can create a mould that mirrors every contour and ensures repeatability during mass production. Precision is essential, as even a small deviation can affect assembly, function, or durability.

Material selection for the mould is another key responsibility. Many moulds must withstand high pressure and temperature during the injection process, so the maker chooses materials that resist deformation and wear. Steel types, hardness levels, and heat treatment procedures are carefully considered. These decisions influence mould lifespan and contribute to stable production cycles.

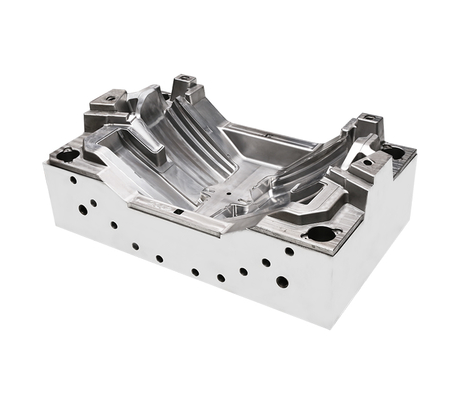

During construction, the Plastic Injection Mold Maker uses machining tools such as milling machines, grinders, and EDM equipment to carve detailed features into the mould. Each operation must follow strict measurements to guarantee proper alignment and function. The maker also ensures smooth surfaces where needed, as surface quality affects how plastic flows and how the finished part appears once ejected.

Cooling systems are an important element within a mould. The maker designs channels that regulate temperature to prevent warping or shrinkage. By managing heat distribution, the mould can produce components with consistent dimensions. Proper cooling also shortens cycle time, enhancing overall efficiency without compromising accuracy.

In addition to technical crafting, a Plastic Injection Mold Maker must consider practical manufacturing needs. This includes planning parting lines, selecting gate positions for material flow, and designing ejection systems that remove parts without causing damage. These features influence both the quality of the product and the ease of production.

Mould makers adapt to new design styles, materials, and performance requirements. Many products now use intricate shapes or textured surfaces, requiring advanced machining techniques and careful planning. The maker’s ability to interpret complex designs helps bring innovative ideas into real-world production.

Overall, a Plastic Injection Mold Maker contributes significantly to the creation of everyday items, industrial equipment, consumer goods, and specialized components. Their craftsmanship ensures that plastic products achieve structural integrity, visual appeal, and proper functionality.