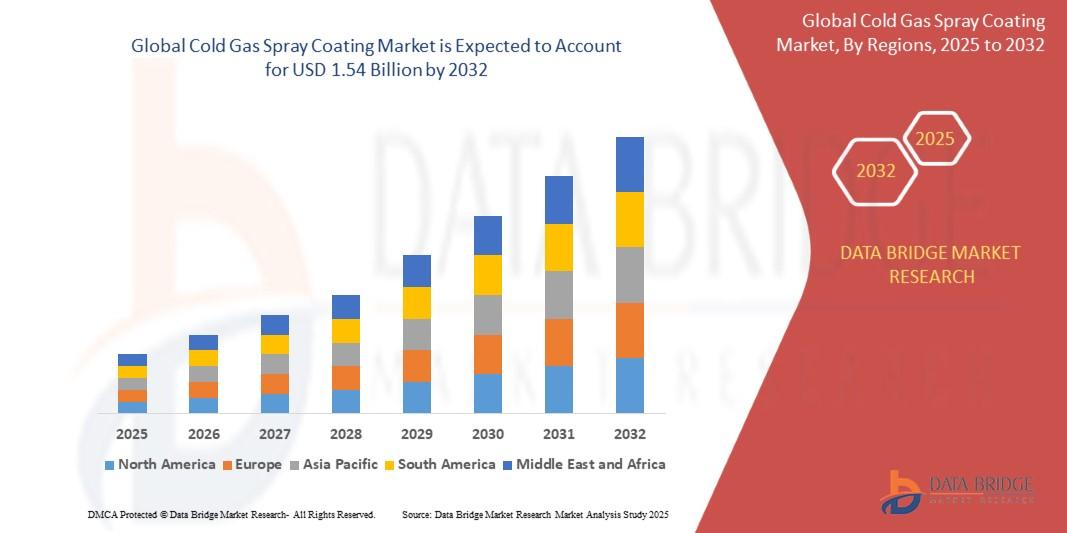

Regional Demand Patterns and Supply Chain Influence on the Polyethylene Foam Market

The Polyethylene Foam Market is significantly shaped by regional demand patterns and localized industrial activity. Demand for polyethylene foam varies across regions depending on factors such as manufacturing intensity, construction activity, packaging requirements, and automotive production. Understanding these regional dynamics is essential for manufacturers seeking to optimize capacity planning, distribution strategies, and market penetration.

Industrialized regions with strong packaging and logistics sectors account for a substantial share of the Polyethylene Foam Market. High-volume shipping, e-commerce expansion, and export-driven manufacturing increase the need for reliable protective materials. Polyethylene foam’s cushioning properties make it particularly valuable in these regions, where product safety during transit is a priority.

According to Polyethylene Foam Market Regional Insights, construction activity also plays a critical role in shaping regional demand. Regions experiencing rapid infrastructure development and urban expansion demonstrate higher consumption of polyethylene foam for insulation, flooring underlays, and expansion joints. Energy-efficient building regulations further reinforce demand in these areas.

Supply chain efficiency is another key factor influencing the Polyethylene Foam Market at a regional level. Regions with well-developed chemical manufacturing infrastructure benefit from easier access to raw materials, skilled labor, and transportation networks. These advantages reduce production costs and improve delivery timelines, enhancing competitiveness. Manufacturers often establish production facilities close to major end-use industries to minimize logistical challenges.

Emerging industrial regions contribute to incremental growth in the Polyethylene Foam Market. As manufacturing capabilities expand and consumer markets grow, demand for packaging, automotive components, and construction materials increases. This creates opportunities for producers to expand their geographic footprint and diversify revenue streams.

Regional regulations and environmental policies also affect market dynamics. Regions with strict sustainability standards encourage the adoption of recyclable and eco-friendly polyethylene foam products. Manufacturers operating in these markets invest in cleaner production technologies and sustainable product lines to maintain compliance and market access.

In summary, regional demand variations and supply chain considerations play a crucial role in shaping the Polyethylene Foam Market. Companies that effectively analyze regional trends and align production and distribution strategies accordingly are better positioned to capture growth opportunities and maintain long-term competitiveness.