Automotive Plastics for Electric Vehicle Market Size, Share, Growth, and Forecast

Introduction

The Global Automotive Plastics for Electric Vehicle Market is witnessing strong growth as electric mobility accelerates worldwide. Plastics have become a crucial component in modern electric vehicles (EVs), offering lightweight properties, design flexibility, corrosion resistance, and cost-effectiveness. With the global EV industry expanding rapidly, the demand for advanced plastic materials to enhance efficiency, reduce vehicle weight, and improve sustainability is surging.

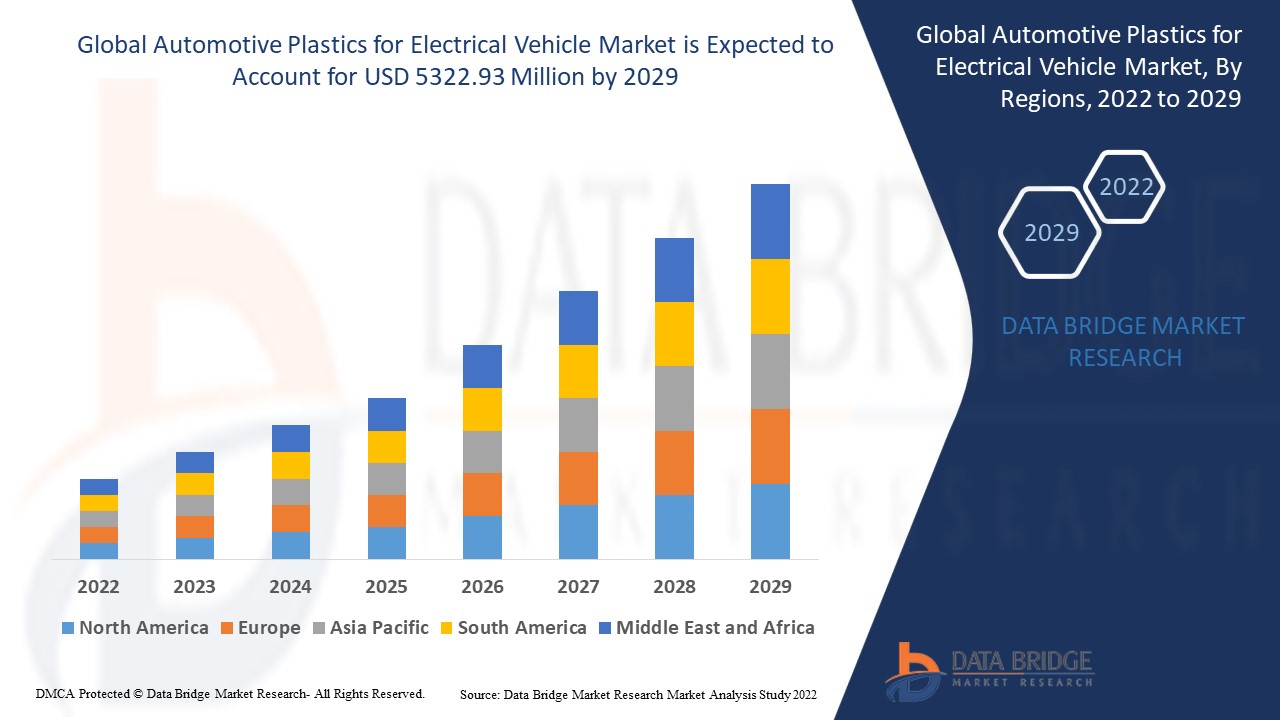

Data Bridge Market Research analyses that the automotive plastics for electrical vehicle market is expected to undergo a CAGR of 27.40% during the forecast period. Automakers are increasingly turning to high-performance plastics for applications ranging from battery casings and interior components to structural parts. The shift toward clean energy transportation and stringent emission regulations are key factors fueling this demand.

Market Dynamics

The Automotive Plastics for Electric Vehicle Market is driven by the growing adoption of EVs across global markets. Weight reduction is a critical priority for automakers, as lighter vehicles require less energy and extend driving range. Plastics are replacing metals in several applications due to their high strength-to-weight ratio.

In addition, advancements in polymer technologies are enabling the production of materials that can withstand high temperatures, provide excellent insulation, and offer improved safety. These properties are particularly important in battery systems, wiring harnesses, and thermal management solutions in EVs.

Government regulations to reduce vehicle emissions and improve fuel efficiency further strengthen the market outlook. Subsidies and incentives for EV adoption in regions such as Europe, Asia-Pacific, and North America are also encouraging automakers to scale up production and incorporate more plastic-based components.

However, challenges such as recycling limitations, environmental concerns regarding plastic waste, and fluctuating raw material prices remain hurdles. Nonetheless, opportunities lie in the development of bio-based and recyclable plastics, which align with sustainability goals while meeting the rising demand from the EV industry.

Market Segmentation

The Global Automotive Plastics for Electric Vehicle Market can be segmented by material type, application, and vehicle type.

By material type, the market includes polypropylene (PP), polyurethane (PU), acrylonitrile butadiene styrene (ABS), polycarbonate (PC), polyvinyl chloride (PVC), polyamide (PA), and other engineering plastics. Polypropylene and ABS dominate the market due to their versatility and strength, while advanced engineering plastics are increasingly used in high-performance EV applications.

By application, the market spans interior components, exterior body panels, under-the-hood parts, and battery systems. Interiors hold the largest share, as plastics are widely used in dashboards, seat components, and trim. Battery casings and structural reinforcements are growing applications as the EV market scales.

By vehicle type, passenger electric vehicles represent the largest demand segment, driven by high production volumes and rising consumer adoption. Commercial electric vehicles, including buses, trucks, and vans, are also contributing to growth as fleet electrification gains momentum worldwide.

Regional Insights

Regional Insights

The Automotive Plastics for Electric Vehicle Market shows diverse trends across global regions.

North America is a key market, supported by strong EV adoption in the United States and Canada. The presence of leading EV manufacturers, investments in battery production, and government incentives drive demand for high-performance plastics.

Europe is at the forefront of EV innovation, with countries like Germany, France, and the UK pushing for electrification and stricter emission standards. The region’s strong automotive ecosystem and sustainability focus support the expansion of plastics use in electric mobility.

Asia-Pacific is the fastest-growing market, led by China, Japan, South Korea, and India. China’s dominance in EV production, coupled with large-scale government initiatives, makes it the largest consumer of automotive plastics for EV applications. Japan and South Korea, with advanced materials and automotive expertise, further enhance regional growth.

The Middle East and Africa are witnessing gradual adoption, particularly in the UAE and South Africa, where EV infrastructure is improving. South America, led by Brazil, is also emerging, with rising EV penetration supported by government initiatives.

Competitive Landscape

The Global Automotive Plastics for Electric Vehicle Market is competitive, with key players focusing on innovation, sustainability, and strategic partnerships with automakers. Leading companies include BASF SE, SABIC, Covestro, LyondellBasell Industries, Dow Inc., DuPont, and LG Chem.

These companies are investing in advanced polymer solutions that offer lightweighting, heat resistance, and recyclability. Collaborations with EV manufacturers are common as suppliers aim to co-develop customized materials for battery systems, interiors, and structural parts.

Mergers, acquisitions, and expansion of production facilities in Asia-Pacific and Europe are shaping competition. Companies are also investing in bio-based and recycled plastics to align with global sustainability initiatives and circular economy goals.

Market Trends and Innovations

Several innovations are influencing the Automotive Plastics for Electric Vehicle Market. Bio-based plastics and recycled materials are gaining traction as automakers aim to reduce carbon footprints and meet sustainability targets.

Lightweight composites, such as carbon fiber-reinforced plastics, are being integrated into EV designs to further reduce vehicle mass and extend driving range. Improved flame-retardant and thermal-resistant polymers are being developed to enhance safety in battery systems.

3D printing of automotive plastics is another emerging trend, offering design flexibility, cost savings, and rapid prototyping capabilities for EV components. Smart plastics with sensor integration are also being explored to support advanced driver assistance systems (ADAS) and connected vehicle features.

Future Outlook

The future of the Automotive Plastics for Electric Vehicle Market is promising, with an expected CAGR of 10% to 12% during the forecast period. As EV adoption accelerates, demand for lightweight, durable, and sustainable plastic solutions will continue to rise.

The development of recyclable and bio-based polymers will open new growth opportunities, addressing environmental concerns while supporting the automotive industry’s transition to clean energy mobility. Manufacturers that invest in innovation and collaborate closely with automakers will gain a competitive edge in this evolving market.

With ongoing government support, rapid electrification, and advances in materials science, automotive plastics will remain central to the design and production of next-generation EVs.

Conclusion

The Global Automotive Plastics for Electric Vehicle Market is playing a critical role in shaping the future of sustainable mobility. While challenges such as recycling and raw material costs exist, the growing demand for lightweight, high-performance, and eco-friendly plastics ensures steady market growth. With innovation in materials and rising EV adoption worldwide, the market is set to expand significantly, creating opportunities for manufacturers, suppliers, and automakers alike.

FAQs

What is the projected CAGR of the Global Automotive Plastics for Electric Vehicle Market?

Which material type dominates the demand in automotive plastics for EVs?

How are plastics used in electric vehicle battery systems?

Which regions are leading the adoption of automotive plastics in EV production?

Who are the major players in the Global Automotive Plastics for Electric Vehicle Market?

What role do bio-based plastics play in this market?

How is 3D printing influencing the development of EV components?

Get strategic knowledge, trends, and forecasts with our Automotive Plastics for Electric Vehicle Market report. Full report available for download: Global Automotive Plastics for Electrical Vehicle Market

Browse More Reports:

Global Digital Out of Home (OOH) Advertising Market

Global Educational Toys Market

Global Gallium Nitride (GaN) Powered Chargers Market

Global Glycomics/Glycobiology Market

Global Hydroxypropyl Methylcellulose (HPMC) Market

Global Hyaluronic Acid Market

Global Laminated Tubes Market

Global Lupine Seed Market

Global Medical Plastic Market

Global Natural Food Colors Market

Global Phosphate Market

Global Protein Cookie Market

Global Spouted Pouches Market

Global Testosterone Replacement Therapy Market

Global Tire Material Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com

Automotive Plastics for Electrical Vehicle Size, Automotive Plastics for Electrical Vehicle Share, Automotive Plastics for Electrical Vehicle Trends, Automotive Plastics for Electrical Vehicle Growth , Automotive Plastics for Electrical Vehicle Competitive Outlook